The ALMA consortium met in Brussels for the first time in person. After 18 months of online and virtual collaboration, it was a pleasure to shake hands with this high performing team that has now proven that the ambitious goals set for lightweighting at the beginning of the project can and will be met. This month marks the halfway point of the project, and the progress has been very promising. One of the important milestones that has been reached is the completion of the Eco-redesign of the ALMA concept vehicle.

Materials

Steel

The project relies on using the latest of materials in its pursuit of maximum weight efficiency. These include new Advanced High Strength Steels (AHSS) as well as advanced sheet moulded composites (SMCs).

ArcelorMittal has been experimenting with some of their latest steels specifically developed for automotive applications. Their high strength and high formability grades for both hot stamping and cold stamping applications allows the parts to be made thinner, thus saving weight while maintaining the stringent safety standards and passing all the necessary (simulated) crash tests. This is one of the key ways to reduce the gross material produced per car.

Beside materials with improved strength and formability, ArcelorMittal also progressed in the development of a grade with a reduced density, which is another way to make car lighter. The manufacturability of the grade was also validated.

Composites

Of particular interest during the consortium meeting was another steel concept: a composite hybrid material that combines two very thin layers of steel material that still remains stiff enough thanks to a polymer layer in between to be used in stiffness-driven application, where the crash requirements are lower.

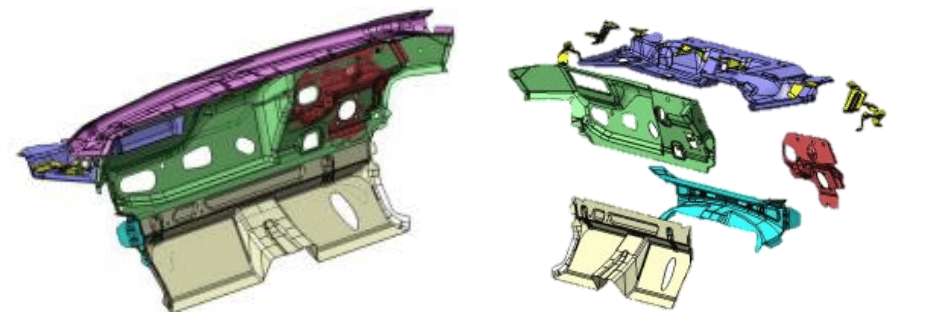

BATZ has been using advanced SMCs to redesign parts that are traditionally made of steel, offering a big opportunity to save weight. This is a challenging activity that has required a lot of creative rethinking of how to redesign or integrate parts in a way that recreates the necessary strength and properties required to maintain safety.

EcoDesign

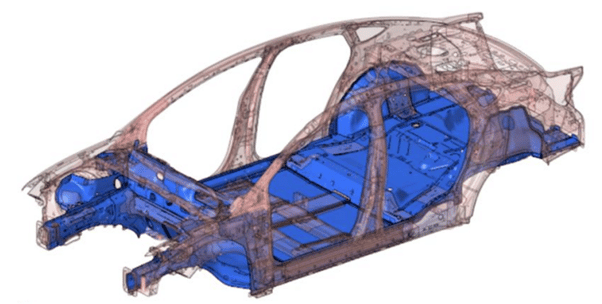

The eco-design of the ALMA concept vehicle is based on the baseline design established earlier. The baseline took a standard ICE production vehicle design and converted it into a BEV. This process usually requires the adaptation of the structure to support a heavy battery pack at the bottom of the vehicle and can greatly increase the total weight of the original structure. In ALMA, the addition of a battery and the necessary reinforcements for safety led to a body-in-white total weight of 727kg. This became the baseline design against which our team would have to use their innovations and creativity to reduce the weight as much as possible.

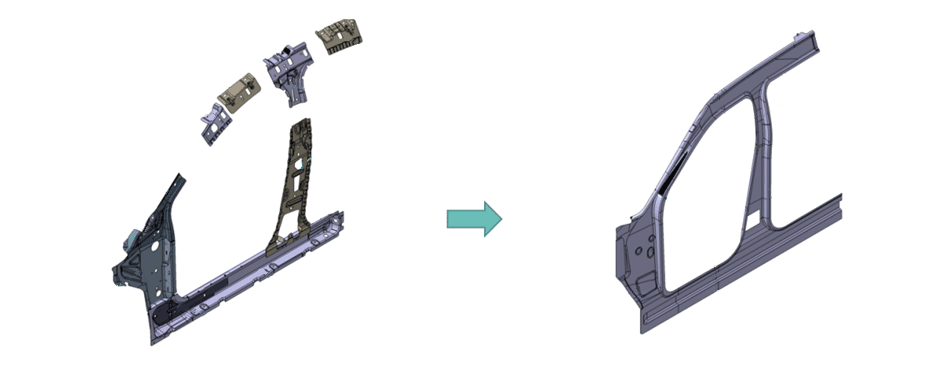

Putting together the new materials and parts, the team compared the feasibility and weight reduction possibilities of applying new steels and the use of SMCs where the properties required to maintain safety allow it. In general steel is still essential for most of the structures, but it was possible to use SMC for parts such as the cowl panel, rear floor panel, rear tray and the battery lid. After applying the redesigned parts to the overall design, and of course some adjustments derived from the full crash test modelling, the total weight savings reached 23.65%! Innovative large Laser Welded Blanks were introduced in the design to integrate many parts into only one thereby easing the assembly operations. This design innovation also delivered a quick win in sustainability thanks to the optimization of the material use and thus the reduction of the process scrap during manufacturing.

Circularity

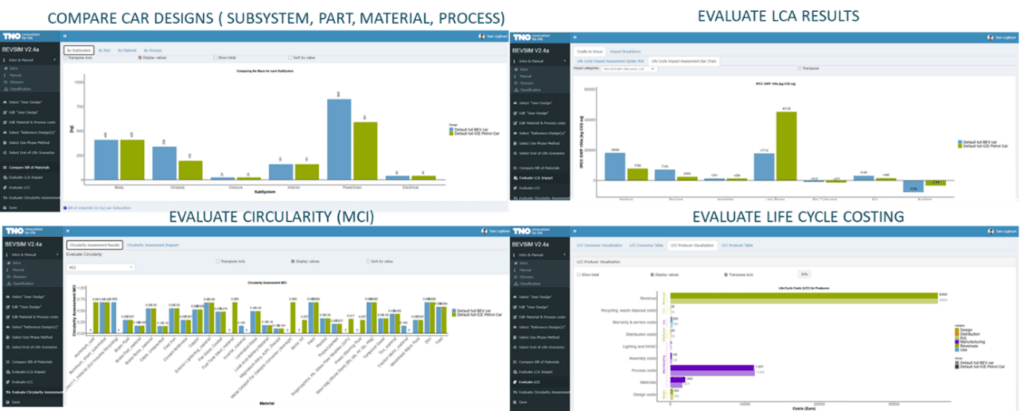

Sustainability does not always correlate to circularity, but it helps. This means that we must pay special attention to circularity topics beyond just reducing weight which may benefit the use phase, but may complicate and increase the environmental cost in all others. The BEVSIM tool as developed by TNO provides an insight into the environmental performance as well as in the circularity of the design.

Lifespan

The first priority in circular thinking is to avoid the end-of-life scenarios as long as possible by enabling lifespan extension strategies. ALMA relies on special technology developed in the space industry for ensuring structural properties and safety of their spacecraft and launch vehicles.

Innerspec was born from the idea of using and measuring how sound propagates through a part to detect whether that part is healthy or not. In fact, the quality of the reflected sound may even be used to diagnose many common faults including cracks, rust, and fatigue. By implementing these systems in the vehicle, it becomes possible to detect issues and fix them before they become a real problem.

Disassembly

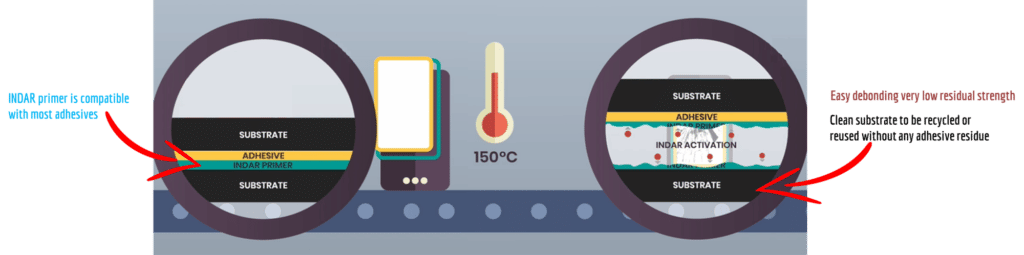

Of course, nothing lasts forever and eventually an end-of-life scenario will be reached. At this stage the main issue is disassembly and how easy (or difficult!) it is to separate the different materials of components. For this ALMA relies on Rescoll’s debondable joining technologies.

The binding agents used to join materials together have a special component that can force the separation of the materials when triggered by special circumstances. In other words, a glue that separates on demand. In this case the retrieved parts can be separated using a simple heating process, allowing the materials to be separated and go further into their own specific recycling processes. This helps ensure a high level of quality in the final recyclate.

Recycling

The use of new materials of course can be both a risk and opportunity. Considering the regulations to increasingly recycle more and more of each car, it is important to make sure that the new materials support that. That is why all the new materials have been tested and assessed on their recyclability.

The new steels should still follow normal steel recycling processes, though this will still have to be proven in practice. The steel composite materials with plastic inside however are a different issue, for this so far there is no effective process found yet to properly separate the metal from the plastic. This of course could be changed through the application of de-bondable technologies at design time.

SMC’s are a more complicated issue. With the current technologies, it is not easy to recycle or recover the constituent materials without much degradation. In the laboratory the most successful strategy so far has been to use pyrolisis, which can provide several fractions that can be used for energy, and at least one useful fraction that can serve as a raw material in some manufacturing processes. There are also some solids left over that include the fibres but at a length and quality level that severely limits their application, so they might be in the end more use as a source of energy.

The experiments will continue using other available techniques, such as solvolysis. However the results point to the imperative of improving the materials and design to include debonding and separation technologies to facilitate recycling at a higher level of value.

LifeCycle Analysis

Applying innovative materials and new processes is not always clearly the most sustainable path – often the materials can have a greater initial cost both economically and environmentally. These higher costs can be made up for along the lifecycle, which is why ALMA targets manufacturing, use, and end of life phases all as part of the total solution. To make sure that we achieve an overall sustainability improvement we can use LCA analysis to compare different options.

TNO has developed and launched the BEVSIM tool specifically created to simplify these types of analysis for the automotive sector. The tool incorporates a multitude of Lifecycle Inventory datasets from each stage in the lifecycle so that the environmental impact can be assessed accurately from cradle to cradle. So far, 278 LCI datasets have been used from raw materials, processing and part production, assembly, use phase, and end of life. To give most realistic result possible in terms of circularity, it also includes datasets on the avoided production of energy, materials and products (parts).

The tool was introduced to the public at a webinar in April 2022 – check here if you missed it.