Access to affordable, efficient, reliable and sustainable energy lies at the core of improving quality of life, creating jobs, fostering economic development and resilience, while accelerating the transition to clean energy. This energy agenda is underscored by the United Nations Sustainable Development Goal 7 (SDG 7), which sets a target for universal energy access that is affordable, reliable and modern for all by 2030.

Today (October 12), the second edition of the European Energy Efficiency conference, organised by the European Alliance to Save Energy, was held in Brussels to discuss the same agenda.

The central question guiding this conference is:

How will energy efficiency as a cost-effective and socially fair decarbonisation solution

help achieve the EU Green Deal targets?The IEA asserts that a transition to a net-zero system by 2050 will require early commitments to energy efficiency.

For an energy efficient future, these four plausible solutions proposed by IEA will help us get there:

- To align with IEA’s Net Zero Scenario, countries need to double efficiency improvements to over 4 per cent annually this decade. Result? Reduction of global energy demand by 190 exajoules (EJ) and fuel combustion-related carbon emissions by nearly 11 gigatons (Gt) by 2030, translating to one third of current global energy consumption and emissions.

- Quick and full implementation of existing policies will help in delivering nearly three quarters of the doubling goal by 2030.

- Fastening the pace of efficiency comes with more benefits. For instance, doubling efficiency progress by 2030 will bolster energy security, create 12 million jobs, and help expand the electricity access net to include more than 800 million people.

- From $600bn today to $1.8 trillion annual efficiency-related investments need to be made by the end of the decade.

Complementing these proposed solutions, IEA’s recent efficiency trends also indicate, among others, increasing uptake of efficiency technologies, including electric vehicles. For example,

- The share of EVs in global car sales in 2022 was 14% and is expected to rise to 18% in 2023.

Although noteworthy, simply shifting production from internal combustion engines (ICEVs) to electric vehicles (EVs) to improve efficiency is inadequate and short-sighted.

The point is not to produce more EVs in the first place, rather ensuring the ones that are already operational to be in circulation for a longer time.

After reaching end-of-life, the EVs must be dismantled in an eco-friendly way and its components, materials recycled and reused in an existing EV. This will reduce our reliance on virgin materials. That’s why the transition to a net-zero system will require a nuanced and a systems thinking approach to validate new EV technologies and end-of-life disposal.

ALMA, an EU Commission funded project, has factored the environmental trade-offs associated with this transition. An interdisciplinary team of engineers, researchers, scientists are working hard behind the scenes to apply a systems thinking approach to ensure ALMA’s novel electric vehicle structure accounts for environmental impacts of its innovative materials right from design to end-of-life (EOL) phase. This means we pay special attention to circularity topics beyond just reducing weight, which may benefit the use phase, but may increase the environmental cost in all others.

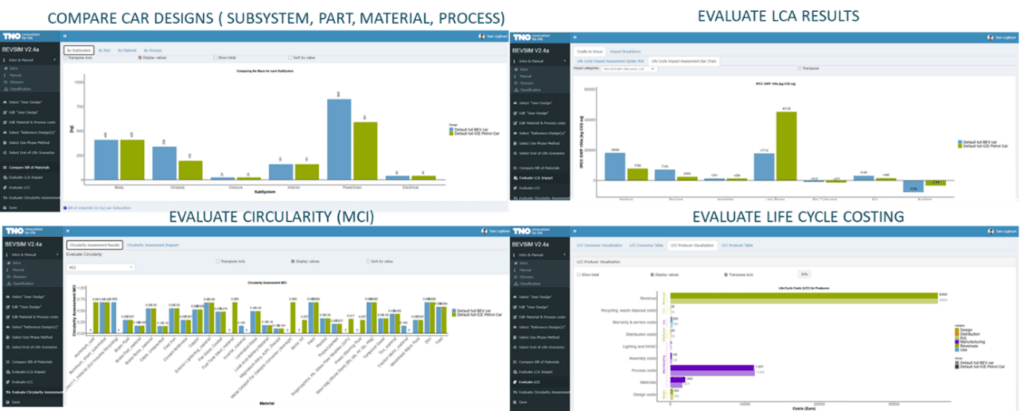

Our BEVSIM tool aims to achieve this task in two steps:

- To extend and refine the life cycle assessment tool with new materials and components as well as options for recycling and re-use;

- Full Life Cycle Assessment (LCA) including sensitivity analysis of the proposed novel solutions compared to “conventional” electric vehicles.

Our novel electric vehicle’s design will be supported by Eco-Design principles. Circular approaches, such as “right material for the right application”, “design for assembly/disassembly” are used to encourage long-life service and integrity to enable reuse, recycling and recovery at the end-of-life. To achieve this, both the full vehicle and the subsystems/components design will be performed in iterative loops through CAD Assisted Engineering (CAE) analysis and entirely supported by the Life Cycle Assessment (CLA) and Life Cycle Cost (LCC) analysis.

Including LCA is one piece of the larger EV lightweighting puzzle, especially because it requires an understanding of novel material compositions and corresponding end-of-life solutions, such as recycling and reusing capabilities. In this case, consortium partner RESCOLL developed an innovative reversible assembly method using debondable adhesives and primers that will enable efficient separation of materials at the end-of-life that is both cost-effective and sustainable. In other words, a glue that separates on demand when applying heat! The reversible assembly method will be implemented considering the BEV’s structural integrity.

What this means:

- Binding agents have a special component that can force the separation of materials when triggered with a heating process.

- Ensures easy disassembly of materials for recycling.

- Allows specific recycling streams for separated materials.

- Helps ensure a high level of quality in the final recyclate.

EVs are not a silver bullet to address the climate crisis. However, they offer a pathway to support efficient urban mobility solutions to enable the transition to net-zero by 2050. Care must be taken to mitigate any negative environmental impacts that might be associated with this transition.